On request, we can provide total customisation of packaging in order to reduce production costs compared to printed products.

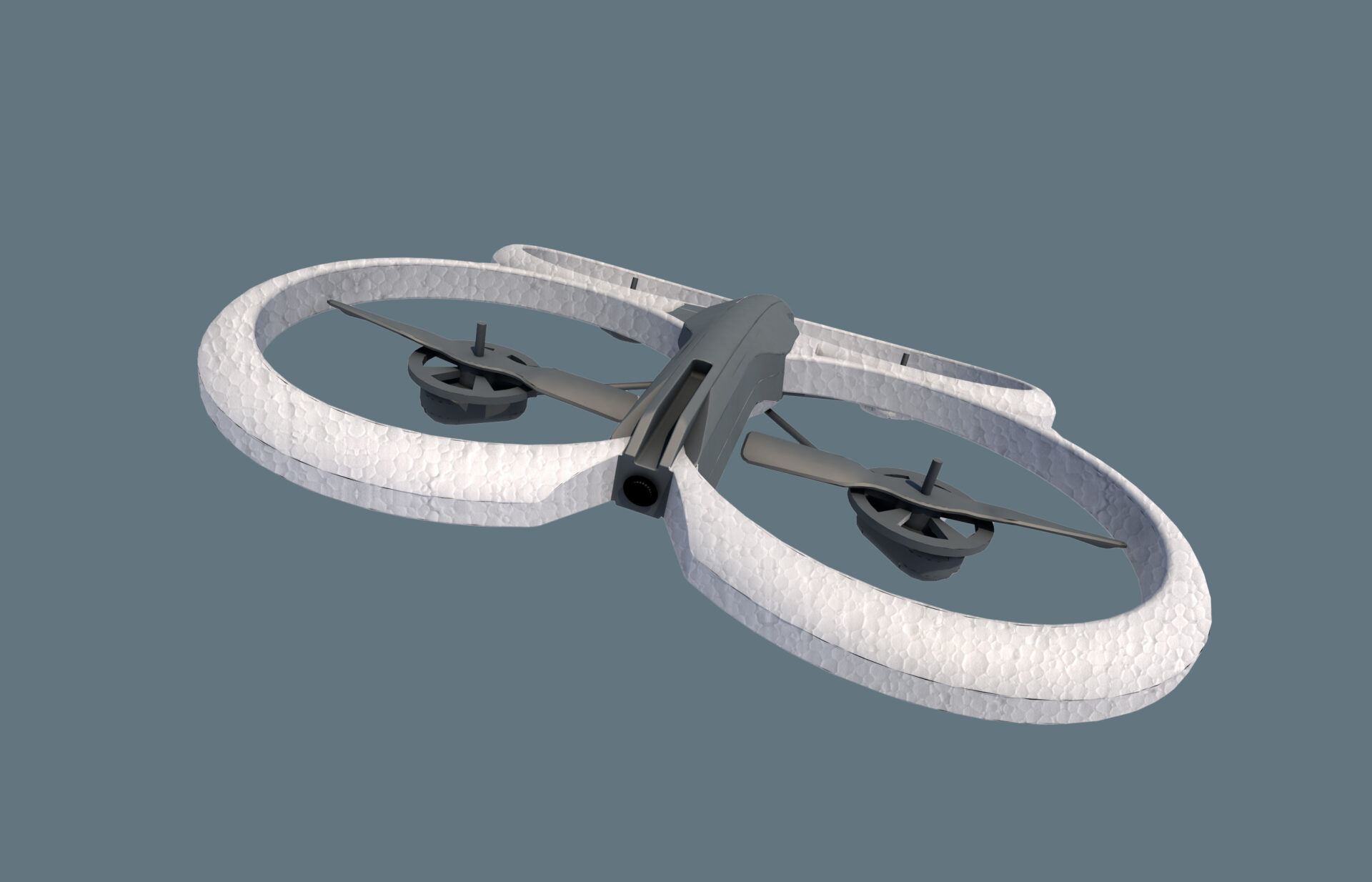

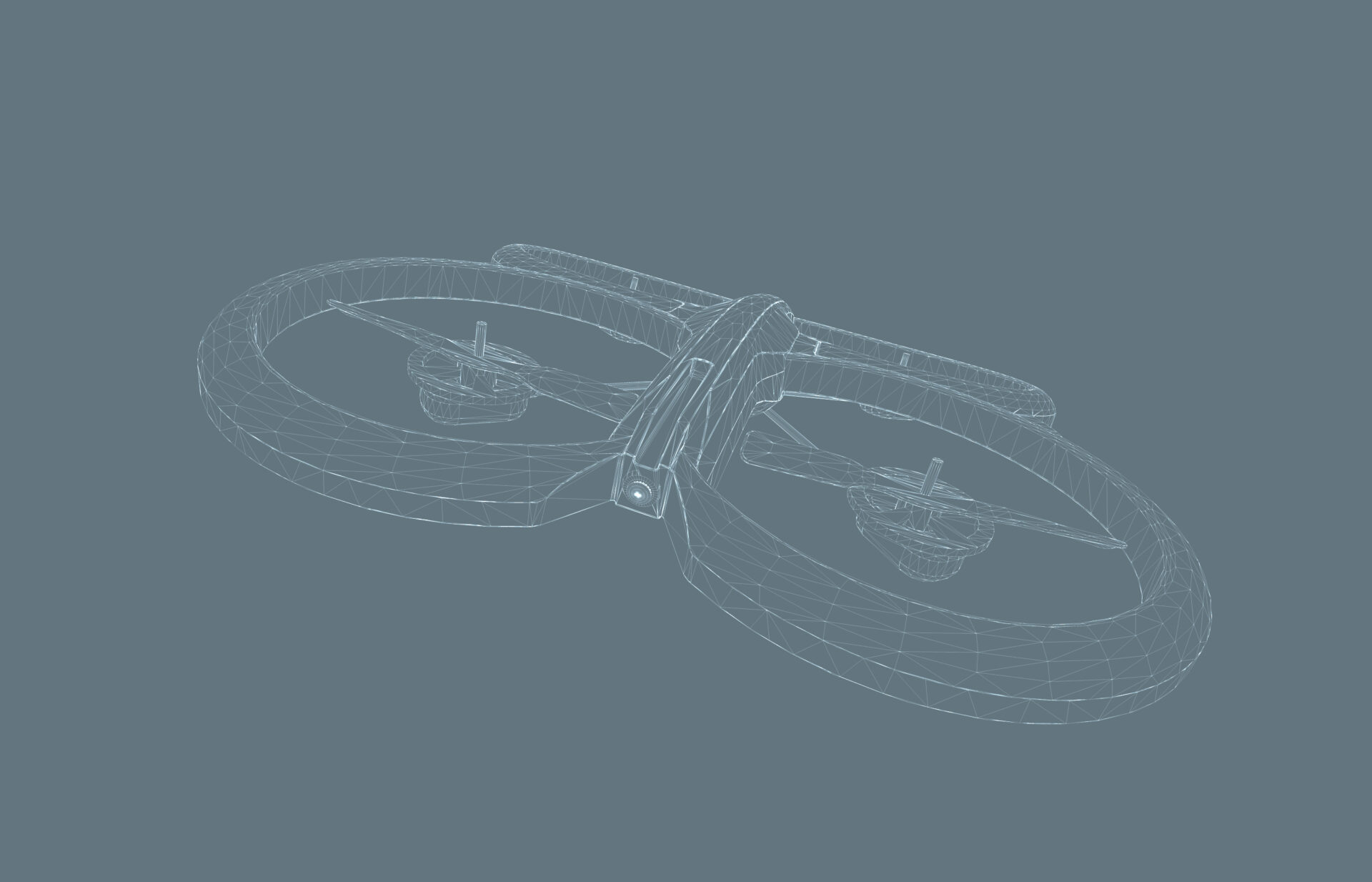

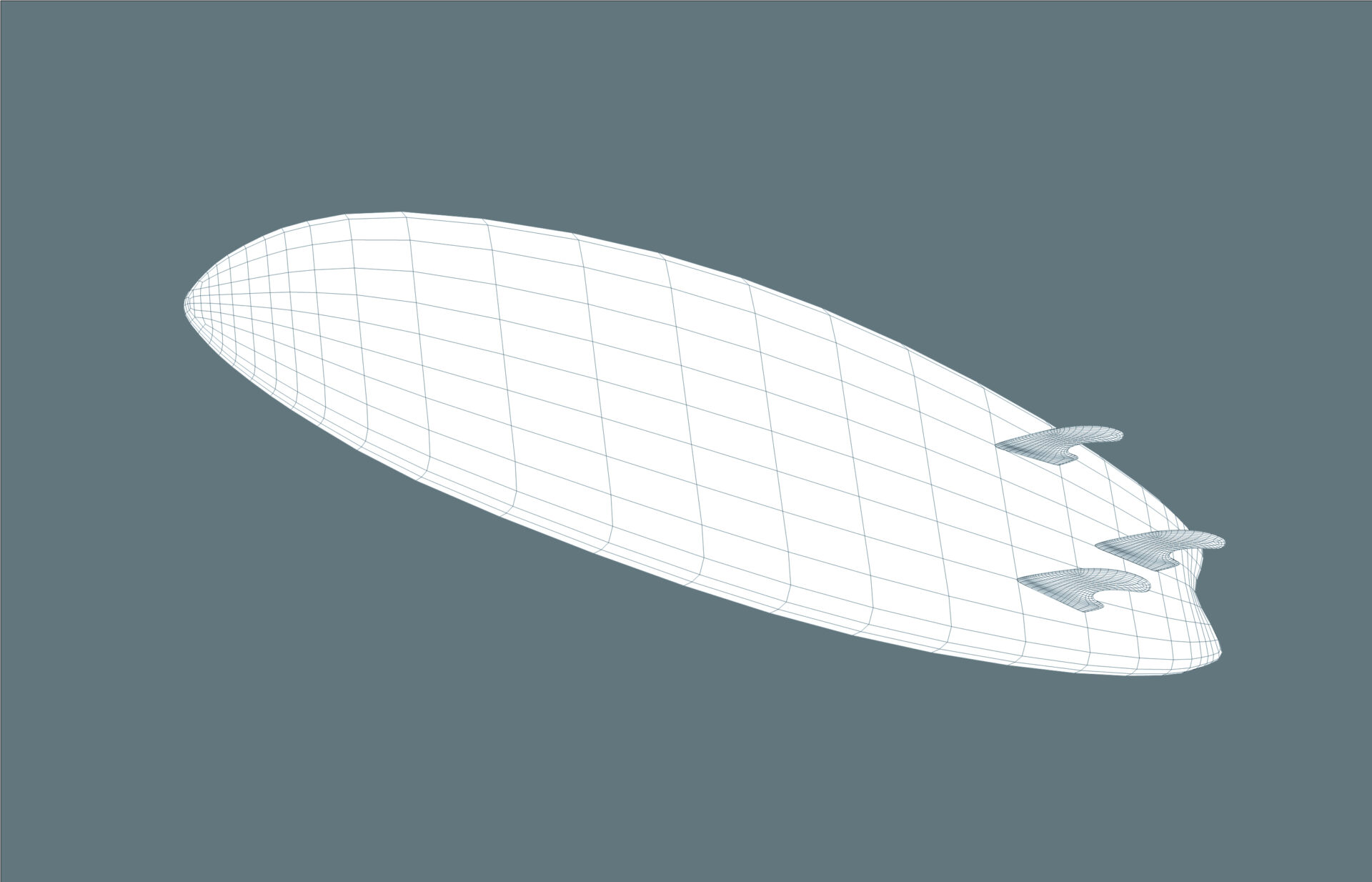

Prototyping

and 3D printing

10 reasons why prototyping is essential

Prototypes can be difficult to produce. Costs can often make them unfeasible.

Believing these ideas can cost a lot more in terms of money and time. Prototyping is the first stage of the journey to market, revealing hidden obstacles and unforeseen challenges, as well as the initial look and feel of the part. Why wait until the production phase to discover problems, when you could have discovered and solved them earlier, at a much lower cost?

Here are 10 reasons why prototyping makes good business sense:

- Adapting the project. We have already mentioned this aspect, but it deserves to be explored further. On paper or on a computer screen, the problems of a project are not always obvious. With the creation of a prototype, on the other hand, it is possible to hold a version of the proposed product in one’s hands and determine which aspects work and which need to be improved. This is an opportunity to gather more precise requirements and get feedback from the market.

- Adjust colours, textures and shapes. Now that you can see your product, what would you change to make it more marketable?

- Quality assurance. By testing the prototype, it is possible to identify any problems that produce defects in the product. You can develop quality control methods and standards before starting full production.

- Measure acceptable tolerance levels. This is an opportunity to decide whether any changes to the design can make the production process more economical.

- Knowing the true cost of production. Prototypes help engineers understand the amount of material needed, helping them to accurately quantify the real cost per unit of mass production of their product.

- Improving product integrity. A prototype makes it possible to verify any structural weaknesses in the product that could compromise its functionality. You can solve the problem immediately and control the costs. It also highlights any design unknowns and avoids downstream discoveries.

- Finding efficiencies and savings. At this stage, you can carefully examine your processes and see if you can consolidate production steps to reduce labour, equipment and raw material costs.

- Modify the tools. Once you have made your prototype, you may realise that efficiencies can be achieved by modifying tools and equipment.

- Making a more durable product. You will be able to assess whether you are using the right fasteners and other components to make a durable product.

- Conflict resolution. If your engineers disagree on a product design, prototyping allows them to understand which features work best and why. The result optimises the project, providing the best possible product.

A variety of industries, including automotive, construction and electronics, regularly produce prototypes before starting full production. These initial prototypes are often discarded because they are impractical, difficult to produce and not marketable. In most cases, however, prototypes tend to offer new ideas and arouse enthusiasm for moving into the production phase.

3D printing

With recycled filaments

Once the prototype design has been realised, we will deal with the printing of the reference model for the empirical analysis of criticalities. What are the advantages of 3D printing?

The main advantages of 3D printing are: cost reduction, less waste, time reduction, competitive advantage, error reduction, confidentiality, production on demand. As far as recent inventions are concerned, the advantages of 3D printing make it one of the most promising technologies. Additive technology is one of the greatest advantages of 3D printing: it opens up a whole new way of creating products and offers many advantages over traditional production methods. There are different types of 3D printing technologies, but the advantages of 3D printing discussed here are applicable to the entire industry. Thanks to its speed of design, high levels of precision and the ability to make informed decisions, the following advantages of 3D printing make this technology a real prospect for companies, but also highlight its importance in future production techniques.

Lower travel costs

One of the biggest advantages of 3D printing is that it can help reduce the distance a product travels. Since 3D printers are able to create a product from start to finish, designers can design the product in one country and email it to another country for production. There is no need to create prototypes that have to be moved from one factory to another to complete the process. In this way, 3D printing becomes an industry that can be created anywhere in the world without leaving a footprint. As a result, shipping, air travel and road trips are reduced.

In addition to the design and production of prototypes, it is also possible to produce parts on-site, which can significantly reduce the carbon footprint.

Less waste, more sustainable

The traditional production process is mostly a subtractive process, in which raw material is wasted and reused several times, resulting in high costs and waste. One advantage of 3D printing is the unique way in which it builds the product with very little waste, called additive manufacturing. While more traditional methods involve waste that can be reused or recycled, it takes time and effort to determine how and when the waste will be used. This makes large 3D printers a very sustainable option.

Thermoplastics, for example, can be melted, hardened (cooled to a solid state), melted again, hardened again and so on. Therefore, production ‘waste’ can be reused (thus preventing it from becoming ‘waste’ in the first place).

Provides a greater competitive advantage

With the ability to reduce the time of the prototyping phase, companies can deliver better, improved and enhanced products in a shorter time. Giving a competitive advantage over the competition. But it also allows for earlier product development, creating prototypes more frequently until the product is perfected and ready for production, creating a highly effective product launch.

The competitive advantage of 3D printing is taken to the next level with our 3D printers. The ability to create a full-scale prototype allows designers to think differently about the products they design. In business, it is important to show customers or investors the products you intend to offer. But producing a product that one might not even like can prove costly, so product descriptions are often left to the imagination. This increases the risk of information being lost somewhere during communication and this can cause serious problems at some point. One of the advantages of 3D printing is that it allows you to quickly create a product that people can physically hold in their hands, eliminating any worries or miscommunication. Although this is a prototype and may be subject to change, it at least gives a small idea of what the product looks like, offering a more truthful representation than the description.

Confidentiality

Continuous prototyping and in-house production with a 3D printer ensure that designs never leave the company premises, safeguarding your intellectual property. No third party will ever be able to claim your innovations. Every innovative project is kept in-house, so there is no longer any need to worry about confidentiality.

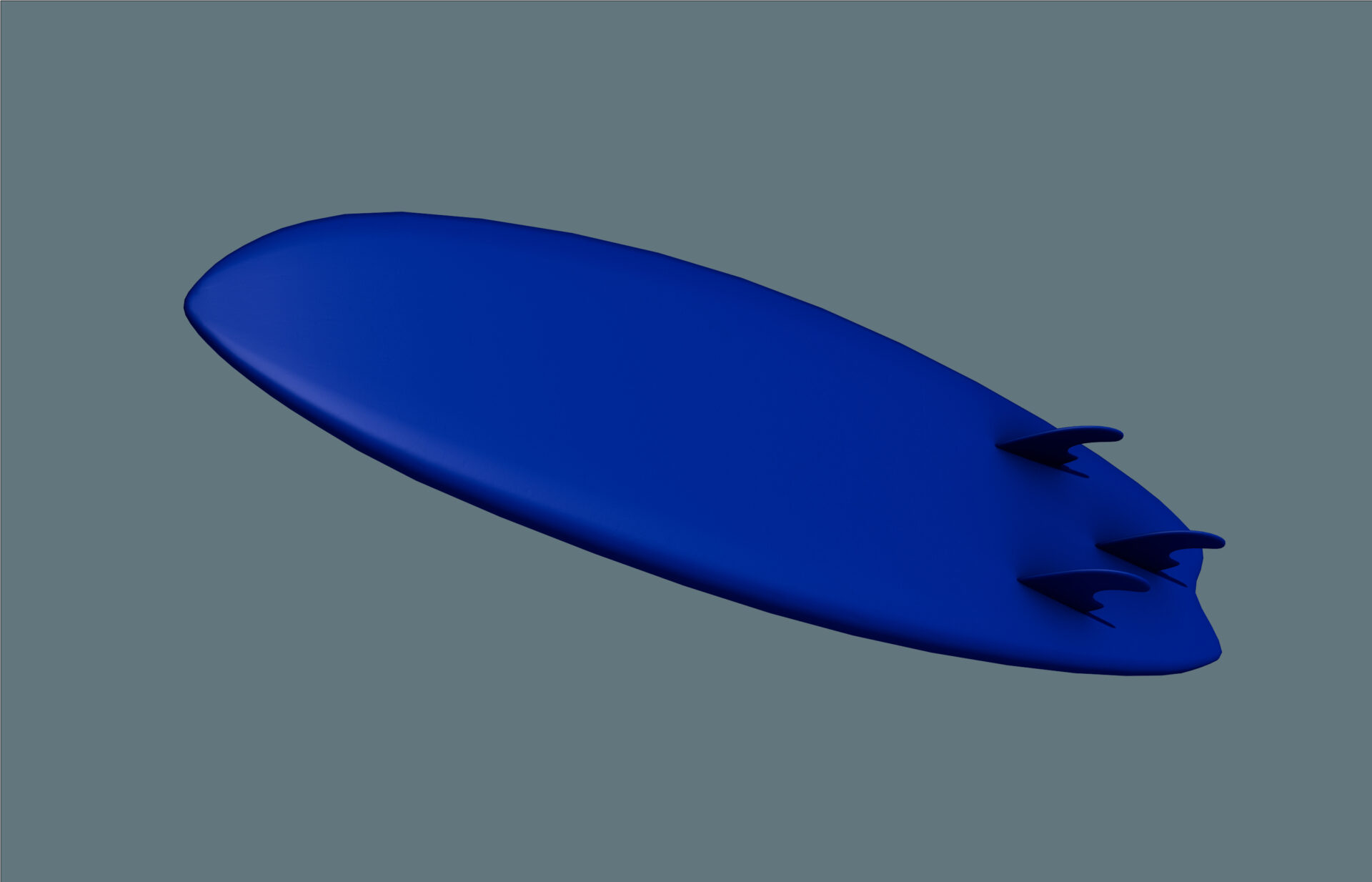

Production on demand

The ability to have complete freedom in design is an enormous advantage of 3D printing. It also allows designers to customise designs. Since 3D printing is perfect for the production of individual parts in a single process, it means that the possibility of customisation is an advantage to be exploited. For this reason, many sectors such as the medical and dental sectors have embraced 3D printing and design due to the possibility of creating customised implants and aids. In fact, sports equipment can be created to fit athletes and thus customised, person-specific parts can be created in a way that has never been seen before.